|

BigCam |

|

The size and form factor of BigCam has been chosen to match the Thorlabs 60mm cage system. Thorlabs hardware is reasonably priced and very well made, and pretty common in optical labs around the world. Plus, they ship Lab Snacks with every order.

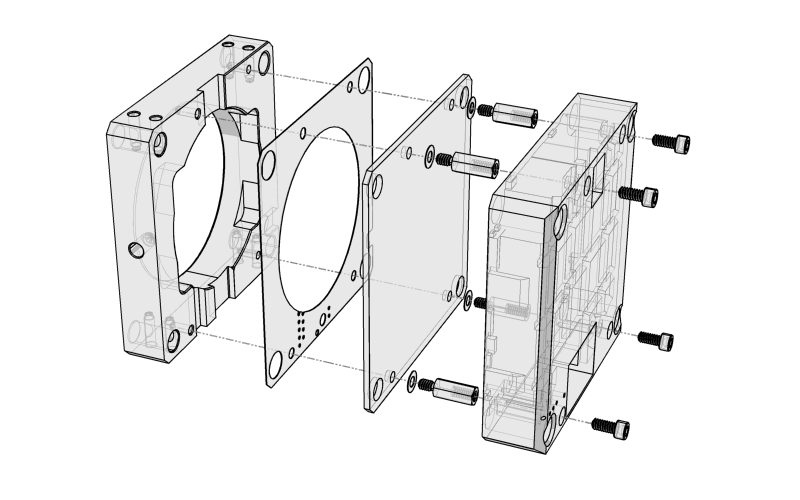

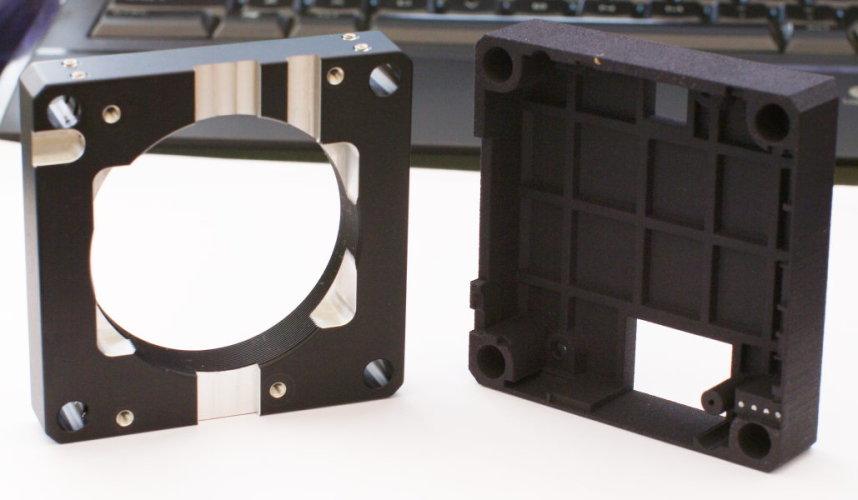

The front of the camera is in fact a modified Thorlabs LCP01, with machined openings for the image sensor corners and four 4-40 tapped holes for the PCB. This guarantees that there will be no issues with BigCam integration into an optical table. The PCB is separated from the aluminum LCP01 mounting plate by a thermally conductive, but electrically insulating adhesive sheet. The sheet is an off-the-shelf material that has been laser-cut to size by Ponoko. The compression force is provided by four 4-40 hex standoffs that attach the PCB to the LCP01. The back of the electronics assembly is protected from accidents by a 3D-printed housing. Shapeways manufactured it without a hitch from nylon, using Selective Laser Sintering. The price was surprisingly low, for a challenging model with a few very thin sections.

|

(c) 2011 Stanislaw Skowronek

Contact me: skylark unaligned org (figure out where to put the @ and .)